BIM expert showcases his hidden talent – woodworking

When Rolly Stevens started woodworking 19 years ago he never expected to use it in his professional career. He picked it up when he first moved in with his wife. At the time they didn’t have any furniture, so the two shopped around, and quickly realized that most furniture is expensive and not well made.

Stevens struck a deal with his wife’s grandfather, who had a small woodshop built onto his garage in Brooklyn Center. Stevens bought the lumber and his wife’s grandfather taught him how to make a coffee table and end tables. A testament to Stevens work, these pieces are still in his living room to this day.

While he does woodworking on the side, Stevens is a virtual designer by trade. In his position at Ryan Companies, he works as a virtual design manager. “Stevens really knows how to wow customers with his Business Information Modeling (BIM)/Revit “show.” Customers can immediately see how the project team can help improve their buildings, workflows and routine business operations,” said Mike Prefling, Director of Virtual Construction at Ryan Companies. On a recent design project for Ryan Companies, for example, Stevens demonstrated how specific mechanical data could be extracted and exported to the customer’s facilities management program. If something fails – such as an AC unit – the customer could access all the information on the unit, right down to the serial number and warranty and service history, to facilitate fast repair or replacement. He says he is able to “mine information from various models so it can be used in customer databases,” or he helps create those databases for them.

Stevens’ woodworking skills became known during Ryan Companies week-long charity event at its Minneapolis office that is held yearly, called Ryan Gives Back. A part of this big event is a silent auction. For this event, Stevens created wooden toys to be auctioned.

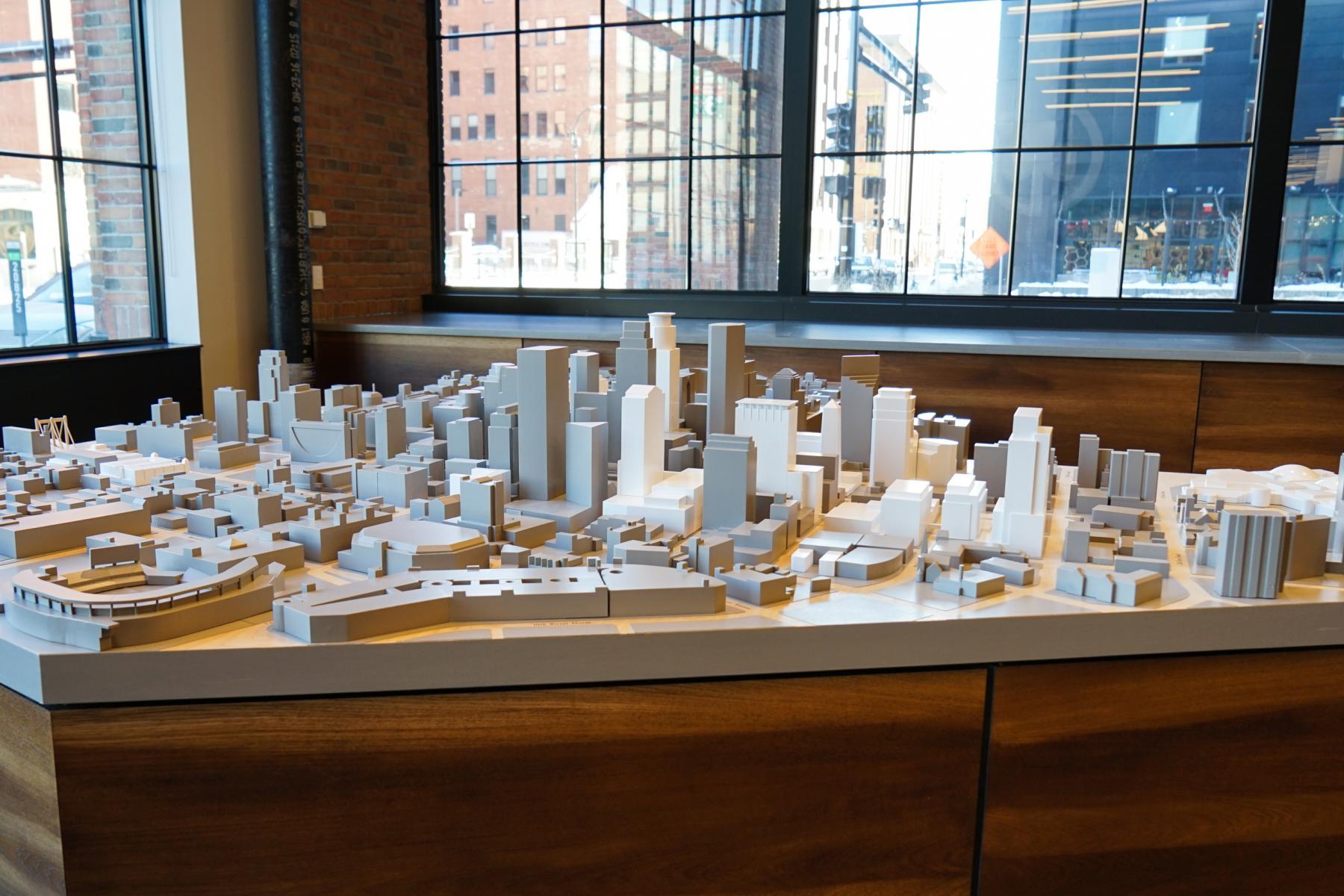

After seeing Stevens work, leadership at Ryan Companies approached him about a modeling project in January of 2016. They wanted a wood model of the downtown Minneapolis area that would showcase the various projects Ryan Companies owned, managed, designed or built. The project quickly ballooned into something bigger than Stevens expected, but he took on the challenge.

Spending many nights and weekends he conservatively estimated that project took around 750 hours. After three phases of building, the model consists of 150 buildings, three bridges, a lock and dam, and the riverfront that is all made of a paint grade hardwood called Poplar. Some of the buildings in the warehouse district include entire blocks of buildings joined together; he built these buildings as one piece rather than four or five.

Stevens used a combination of tools like Bing Maps, Google Earth and an online building database, Emporis.com, to get sizes and heights of the buildings in the area. He then used Google Earth to get an idea of how much detail to include, so that he could capture the character and unique details of each building.

Stevens’ virtual design skills came into play by using BIM. He used a BIM software called Revit to scale down buildings for the model, using a scale of 1 inch = 50 feet. With this software Stevens was able to print out plans for each building that allowed him to easily transfer the measurements of the buildings, so he could start cutting the wood.

Out of the 150 buildings he worked on, he said the hardest to make was US Bank Stadium. At the time there wasn’t much data out there about the finished building. Stevens only had early architectural models, but a lot had changed during construction. There were 10 sides that had to be mitered (joint made between two pieces of wood at an angle of 90 degrees), along with the sloping roof over the entire building. With the complicated features of the stadium, it took Stevens a week to complete just this building.

The model of Minneapolis was finally complete in September of 2017. Stevens’ work can now be seen in the lobby of Ryan’s new headquarters.